sand mold casting foundry

Rapid Casting Prototype | Batch Sand Casting | Free Mould Design

We specialize in the manufacture of custom sand cast parts for complex structures.

We offer unparalleled casting technology and economical ex-factory prices.

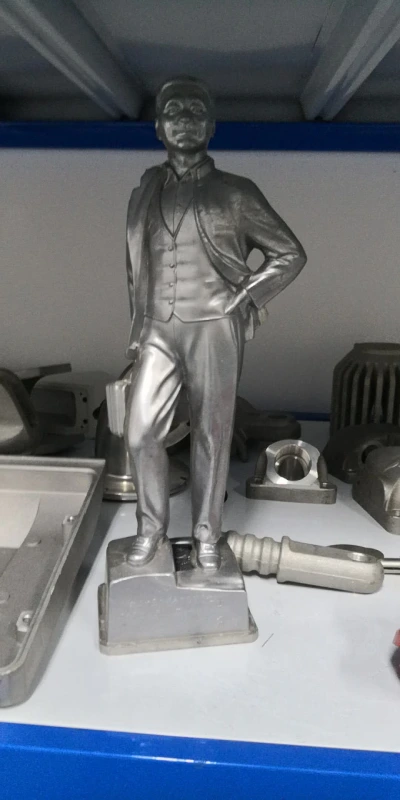

sand casting foundry

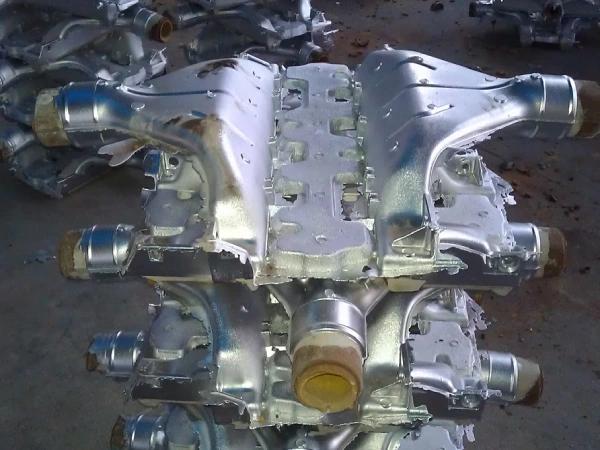

Supro MFG is a well-known china sand casting Foundry in the industry. It has passed ISO9001-2015 quality certification and TS16949 standards. It has a fully automatic molding production line, focusing on green sand molds casting and resin sand casting technology, providing high-quality complex structures for different terminals. Sand casting parts, creating a more economically competitive casting service.

We have more than 28 years of experience in custom sand casting, widely used in: engine parts, cylinder heads, cylinder pistons, frames, brackets, manifolds for high horsepower engines, impellers, casings, construction industry and agricultural equipment.

sand casting material solutions

Supro metal sand casting foundry meets material specifications according to a variety of industry standards and custom specifications, using the most reliable raw materials for the most functional metal casting.

steel sand casting

aluminum alloy sand casting

Visit Supro sand Casting Foundry

Design - Prototype - Molds - Casting

Supro sand casting foundry is an industry-leading sand foundry in China, providing high-quality sand casting parts to buyers from all over the world with the most advanced casting equipment and finishing services.

We have 28 years of sand casting experience, focusing on green sand molds casting and Resin sand casting services, from simple to complex metal sand casting parts, no matter small batch prototypes or large batch orders, we will meet the product needs of various industries and functional applications, providing the most reliable manufacturing solutions, increasing efficiency and saving costs.

Supro sand casting services is the most reliable supplier of sand casting parts for all industrial, commercial, agricultural, construction, transportation and more.

We provide a full range of technical advisory services.

- Manufacturable casting solutions

- Optimize product design to avoid defects,

- Reasonable casting material recommendations.

- Improve the casting scheme to reduce the processing cost as much as possible.

- Aesthetic visual finish.

- Effectively improve material functionality through heat treatment.

- Cost-effective mold design and manufacture, as well as maintenance.

Our sand casting Services

Green Sand molds casting

Green sand casting is a widely used metal sand casting process that uses wet, unbaked sand to make cavities and cores. The main advantage of green sand casting is that the foundry sand can be used many times after filtration, and after mixing with other clays or special minerals (such as: SiO2, kaolinite and montmorillonite), it can effectively improve the casting effect and surface finish requirements.

Supro MFG Sand Casting foundry is good at setting the gate and runner distribution system of green sand molds reasonably, so that the metal solution can be fully filled in the mold cavity until it solidifies, and the sand casting parts can maintain high quality and stability, and increase the economic competitiveness of the parts. .

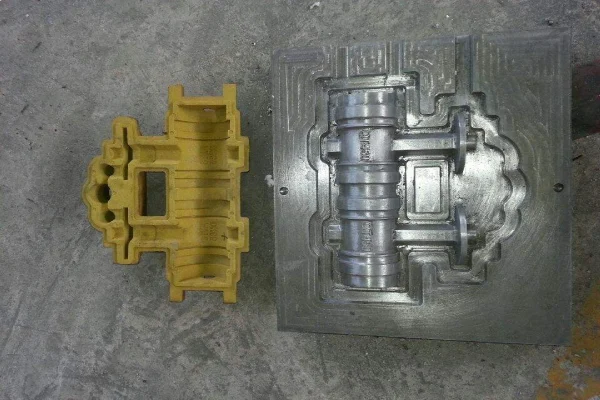

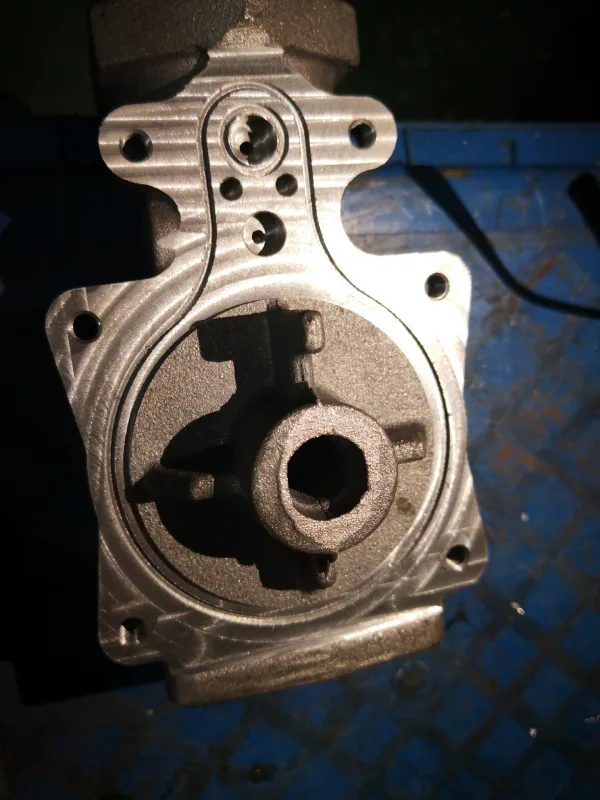

resin Sand molds casting

This is a higher cost sand casting process, also known as shell molds casting. Relying on the resin-containing foundry sand, under the heating of the steel mold (the steel mold will incur higher investment costs), the resin will wrap the sand grains and become hard, resulting in a sand shell with a complex structure, and the inside is the molding mold of the product. cavity, the molten metal solution solidifies and cools in the sand shell, which can achieve very precise sand casting parts with fewer defects and sand holes, and the surface presents a very fine and uniform texture, which is widely used in auto parts, pipe joints, flanges, Sand casting of pumps, valves and other demanding iron and steel parts is now a very popular casting method in the foundry industry.

Supro Sand foundry has full pre-coated resin sand casting production line, more than 70% of orders for sand casting parts use this casting process. Choose Supro MFG and you won’t be disappointed.

China Supro sand casting Foundry

Advantages of sand casting parts

Sand castings offer design flexibility

If your product is in the early stages of development and design, sand casting can offer great flexibility. Changes can be made to accommodate any minor changes in the design, so minor changes are very cheap.

At Supro MFG, we usually choose to use wooden casting molds for product development and casting testing process, which can not only reduce the investment of expensive molds, but also complete the mold manufacturing in a period of time.

Sand mold casting can design a variety of spliced mold shapes, and create casting parts for different application scenarios through different matching.

Moreover, the choice of materials is also variable. After reasonable selection of foundry sand and calculation of shrinkage, various metal alloys can be used to create the complex casting details you need.

In addition, the casting must have a draft perpendicular to the parting line, which cannot be avoided.

Dimensional Control and Consistency

Sand casting can produce a wide variety of different parts ranging in weight from less than an ounce to thousands of pounds. In Supro sand casting foundry, we generally control the size error within the range of ±0.5mm-1mm. According to the design and size requirements of the castings, we will reasonably set the most ideal mold plan, and keep it during batch casting. Stable consistency.

Surface finish for aesthetic vision

The surface finish of sand casting parts is mainly determined by factors such as foundry sand and mold, Supro MFG noticed that sand casting parts with uniform texture are required by many customers, we choose high quality foundry sand, as well as polished aluminum or steel The mold performs cavity molding. Sand cast parts have an aesthetically pleasing surface finish, and through secondary surface treatments, more functional applications can be enhanced such as: mechanical polishing, shot peening, painting, spraying, powder coating, electroplating (chrome, tin, etc.), Acid etched, anodized, galvanized and various other unique polyamide durable coatings.

Cost-effective sand casting parts

Compared with other casting processes, the casting process of sand casting parts is simpler, with fewer steps and lower mold costs. It is suitable for a variety of metal materials, and can quickly create complex casting structures and save expensive machining costs. The process can be applied to simple shapes as well as fairly complex castings, and can be used for all metals such as aluminum, cast iron, ductile iron, copper alloys (brass, copper and bronze), steel alloys, stainless steel alloys, and other complex metals.

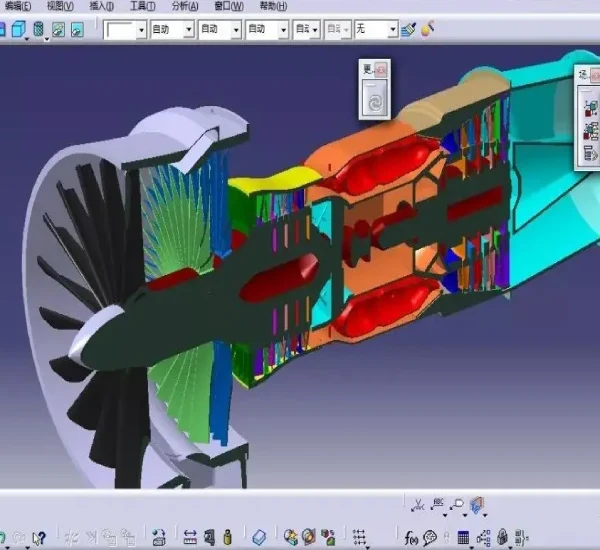

Metal Casting Prototype & Design Services

With professional casting technology and advanced casting equipment, we provide services from design optimization, mold manufacturing to batch casting, etc.

Metal casting products Design

Focus on how you can help and benefit your user. Use simple words so that you don't confuse people.

Rapid Metal Casting Prototype

Focus on how you can help and benefit your user. Use simple words so that you don't confuse people.

Metal Casting Testing and Assembly

Focus on how you can help and benefit your user. Use simple words so that you don't confuse people.

Looking for a reliable sand casting foundry?

- We can help you optimize product design and save costs.

- We can help you with high quality high volume cast parts.

- We can deliver on time and get more sales market opportunities.

- You will benefit from Supro MFG metal casting service.

Industry Application solution

More than 3000+ buyer companies around the world choose to cooperate with Supro MFG Metal Foundry for a long time, and benefit from it, involving industries: Automobile manufacturing, medical treatment, military industry, agriculture, construction, energy and household hardware parts, etc.

- Gearbox and housing

- All types of valve and filter parts, bodies and housings

- Gear

- Pump parts, pump body and housing

- Counterweight

- Water accessories

- Flange

- Flywheel and handwheel

- Building components

- Fence Post Parts

- Marine windows (portholes) and doors, corrosion-resistant fittings, and anchors

- Yachting accessories and parts

- Shipbuilding parts

- Propeller

- Impeller

- Pulleys

- Device enclosure

- Large parts for road trailers

- Large pipe fittings: elbows, Ts, connectors, etc.

- Wind power accessories and enclosures

- Off-Road Gear Parts

- Heavy-duty machine bases and workbenches

Get a Ex-factory quote?

- Send product design.

- Tell me about your ideas and needs.

- Sign the contract & NDA.

- On time delivery of high quality casting parts.