Metal Die Casting

Investment casting

Sand Casting

Custom Molds Making

Precision CNC Machining

metal investment casting foundry

Investment casting is one of the most important casting processes of Supro metal casting foundry, with a complete internal foundry workshop, from product design, mold design, mold processing, precision casting, cnc machining, quality inspection, packaging and transportation, etc. one-stop On-demand manufacturing services.

Our investment casting process includes: Water Glass Investment Casting and Silica Sol Investment Casting, applied in different product designs and cost constraints, to create precise, complex and smooth surface casting parts, closer to the final application shape, reduce precision CNC machining the cost of.

Supro Metal foundry has 25 years of casting experience, whether it is precision casting prototypes, large casting parts, mass casting or casting parts with complex structures, we can rely on professional metal casting technology and advanced casting equipment to meet your needs, on time Delivery of high quality cast parts.

Precision investment casting Services

Silica Sol Investment Casting

Silica sol investment casting is a casting process that is widely used in stainless steel and alloy steel casting parts. Silica sol is used as a binder to build a ceramic shell on the outer surface of the wax mold. It has the characteristics of high precision (CT4~CT6) and good surface finish. The foundry field plays an important role.

Supro MFG is a professional investment casting companies, we utilize silica sol casting for casting parts such as high temperature heat resistant alloys, heat resistant steels, stainless steels, carbon steels, low alloys, aluminum alloys and copper alloys.

Water Glass Investment Casting

Water glass investment casting is a casting process in which water glass is used as a binder to wrap the ceramic shell of the wax mold. The accuracy is better than that of sand casting, but the surface finish is poor. It is suitable for parts with heavy weight or no strict requirements on the external surface. .

At Supro MFG, we rely on water glass investment casting with low material cost and high forming efficiency for part casting of heavier or stronger products with more complex shapes. Such as: agricultural machinery, gears, large bases, and civil engineering components.

SLA 3D printed investment casting

3D printing wax investment casting is an advanced casting process that fills the gap. It can quickly build SLA models through 3D printing technology to meet the casting needs of small batches, high precision and low cost, reduce the investment in molds and production cycles, and increase the demand for rapid prototyping and production. Small batch casting brings huge economic benefits.

As an advanced investment casting company, Supro MFG provides high-precision SLA 3D model casting services, providing cost-effective metal casting solutions for casting prototypes and small batch castings. Such as: precision gears, jewelry, models, small art sculptures, etc.

vacuum investment casting

Vacuum investment casting is the process of completing precision casting in a vacuum state, which can effectively prevent the metal solution from rolling in the ceramic cavity and the pores generated after bursting, which brings internal defects and complex details that cannot be filled to the metal casting.

Supro Investment casting companies provide vacuum investment casting services for thin walled castings as well as castings with intricate details, ensuring that the castings maintain high precision and a very smooth surface.

Visit Supro Metal Casting Foundry

Design - Prototype - Molds - Casting

Supro Metal Foundry is China leading metal investment casting manufacturer, founded in 1997, with continuous upgrading of casting technology and replacement of advanced casting equipment, we have become an industry-leading casting enterprise, covering an area of 8,800 square meters, with three castings workshop, a precision cnc machining and surface coating workshop, has 120 technical employees, 18 quality engineers, and 17 core company management. Provide stable metal investment casting parts supply projects for 3800+ purchasing companies from China and the world.

Whether rapid investment casting prototype or high volume casting, we can provide strong casting capabilities, including: product design and optimization, mold design and manufacturing, metal casting process, quality control, precision CNC machining, material and physical property testing, surface coating , as well as one-stop metal casting services such as packaging and transportation.

Metal investment casting material solutions

We are not only metal casting experts, but also casting materials experts, creating the most ideal metal investment castings through different metal casting materials for perfect mechanical properties and functional applications.

stainless steel investment casting

steel investment casting

copper investment casting

China Supro investment casting Foundry

what is precision investment casting ?

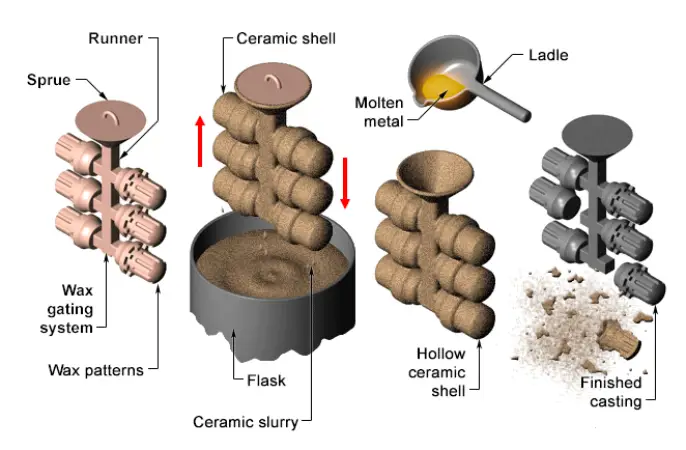

Metal Investment casting, also known as: lost wax casting, is one of the popular metal precision casting processes in the manufacturing industry. The industrial or household wax is molded through a mold, connected into a tree-like structure, and a multi-layer ceramic shell containing silica sol or water glass is wrapped on the outer layer. Metal casting is performed after drying.

Investment casting parts have many advantages to accurately create complex structure of product casting structure and shape, as close as possible to the final shape, compared with traditional sand casting, investment casting parts are more accurate in size and have a better surface finish to reduce precision processing cost.

- Offers greater flexibility in design.

- Provides more details on complex structures.

- Affordable low cost casting molds.

- Multiple alloy options to enhance the performance of cast parts.

- Surface finish Ra 3.2.

- Precision tolerance Min ±0.15mm.

- High-volume casting maintains consistent high-quality delivery.

Precision investment Casting Prototype & Design Services

As a world-renowned investment casting companies, Supro MFG actively provides a range of on-demand metal casting services, starting from mold design to on-time delivery of batch cast parts, without you having to undertake complex technical challenges.

investment casting molds Design

Reasonable mold design and manufacture is an important basis for precision investment casting.

rapid investment Casting Prototype

Focus on how you can help and benefit your user. Use simple words so that you don't confuse people.

metal Casting Testing and Assembly

Focus on how you can help and benefit your user. Use simple words so that you don't confuse people.

Looking for a reliable investment casting manufacturer?

- We can help you optimize product design and save costs.

- We can help you with high quality high volume cast parts.

- We can deliver on time and get more sales market opportunities.

- You will benefit from Supro MFG metal casting service.

China Supro Metal Foundry

metal casting quality control

Create

functional and aesthetic vision

for high-quality

metal casting parts.

- Surface defect inspection.

- Inclusion inspection.

- Internal casting defects.

- Forming cooling defects.

We value the high quality delivery of metal castings, a professional quality control team monitors all casting processes including: surface defects, internal defects, dimensional defects and material composition.

We pay more attention to the function and aesthetic vision of the product, including: oil & air tightness, surface spray (custom color), polishing, painting, etc.

- Appearance and structure inspection.

- Dimensional quality inspection.

- CMM type bit size detection.

- Chemical composition detection (spectroscopy).

- Mechanical property testing.

- Destructive detection.

- Non-Destructive Testing (NDT).

- Assembly and testing.

Industry Application solution

More than 3000+ buyer companies around the world choose to cooperate with Supro MFG Metal Foundry for a long time, and benefit from it, involving industries: Automobile manufacturing, medical treatment, military industry, agriculture, construction, energy and household hardware parts, etc.

Time has changed

What are you looking for?

Get a Ex-factory quote?

- Send product design.

- Tell me about your ideas and needs.

- Sign the contract & NDA.

- On time delivery of high quality casting parts.