Aluminum Alloy casting : Widely preferred for its durability and stability.

Aluminum alloy casting can get customized aluminum alloy parts of any shape and size, with some advantages and characteristics that other metal casting parts cannot compare, such as: beautiful appearance, light weight, heat resistance, corrosion resistance, high strength, easy processing, etc. Favored by many customers, especially in the automobile manufacturing industry, with the widespread use of lightweight and high-strength technology in automobiles, aluminum alloy casting parts are widely used in important automobile parts.

The density of aluminum alloy castings is lower than that of cast iron and cast steel, but the strength is close to that of cast steel, so it also plays an important role in many fields such as aviation industry and industrial machinery parts. Pure aluminum castings have very good corrosion resistance and are often used in outdoor decoration, chemical industry and edible tableware with high salinity.

Aluminum alloy has good casting properties. Due to the characteristics of low melting point, good fluidity and long solidification cycle, after reasonable control of the casting process, it can obtain good intrinsic quality, perfect surface finish, high dimensional accuracy, and high production efficiency. Casting parts with complex structure or thin-walled structure are widely suitable for most casting molding processes, including: sand casting, die casting, permanent mold casting, etc.

Supro casting foundry has strong aluminum alloy casting ability

At Supro MFG, aluminum alloy casting is one of the most important casting processes. We have been focusing on aluminum alloy casting business for more than 25 years. We have a professional casting technical team of 31 people. With advanced casting production lines and rich professional knowledge and experience, we can From product design, mold design and manufacturing, batch casting to packaging and shipping, we provide you with a range of manufacturing solutions.

When your product requires the tightest tolerances and the most aesthetically pleasing surface, you can contact Supro MFG.

As an industry-leading aluminum alloy foundry in China, it has been highly recognized and praised by various industries for its most influential technology and cost-effective casting parts supply services.

Our aluminum casting Services

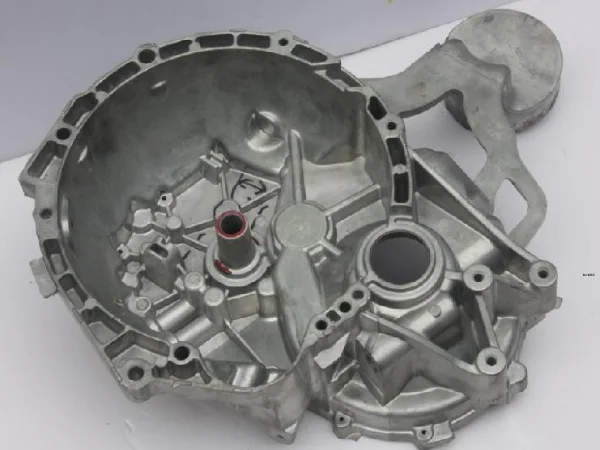

Aluminum alloy castings are made by injecting molten aluminum alloys into different molds, and after cooling and forming, the aluminum alloy casting parts required for the final design are obtained.

aluminum alloy die casting

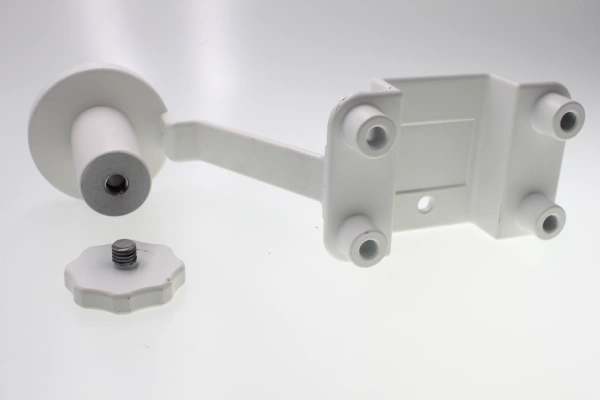

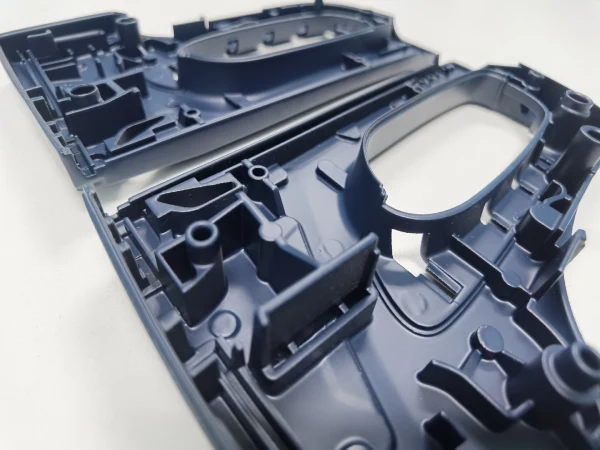

Die casting is very similar to permanent mold casting, but instead of gravity, die casting relies on the pressure of the die casting equipment to inject the metal solution into the mold, including: low pressure die casting and high pressure die casting, which allows the material to more fully fill all the details inside the mold. Die casting is very friendly to create castings with complex structures and thin-walled structures, and is widely used in automotive engine housings, electronic equipment brackets, Led lighting accessories, radiator housings, etc.

Supro MFG has advanced die casting manufacturing equipment to meet the needs of low pressure die casting and high pressure die casting products, we provide the most cost-effective on-demand die casting manufacturing solutions for buyers from all walks of life around the world, and through x-ray, composition analysis, Non-destructive testing, mechanical testing, salt spray testing, etc., to ensure on-time delivery of high-quality die-casting parts.

aluminum alloy sand casting

relying on resin sand or green sand to form a cavity with the shape of the final product under the action of aluminum or steel molds, inject molten metal into the sand mold, and cool to form. Aluminum alloy sand casting is economical, but usually requires secondary machining to achieve close dimensional tolerances, and is also very effective for creating large aluminum alloy cast parts or parts with fine detail, suitable for large-scale casting projects.

At Supro casting foundry, we control the casting process and the element composition of the aluminum alloy reasonably to avoid most of the defect problems, enhance the mechanical properties, improve the casting efficiency, and make the aluminum alloy castings more competitive.

Advantages: high efficiency, low cost, economical, complex structure can be realized, suitable for a wide range of materials

Disadvantages: There are many sand holes and pores, and the surface is rough. It is impossible to build fine details.

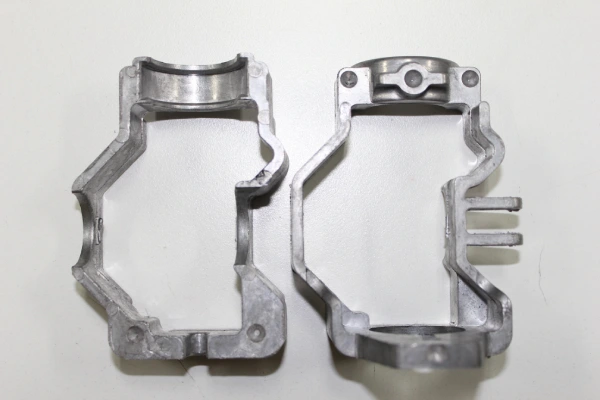

aluminum alloy Permanent mold casting

Creates steel molds and other metal molds or cores. The molten aluminum alloy is cooled and formed inside the mold. This is a reusable metal mold. More often, the aluminum alloy is injected by gravity to fill the mold cavity. Inside. The mold is then separated after cooling and the finished part is ejected or removed.

Supro MFG uses this rapid prototyping casting process to achieve a more consistent microscopic metal structure, increase the density of aluminum alloy castings, and significantly enhance the mechanical properties of the product. It is generally used in industries with high weighing capacity, wear resistance, and corrosion resistance. in demand.

Advantages: Higher product density Fast build time Low product cost High surface finish Finer detailing possible

Disadvantages: High mold cost Does not support design changes Not suitable for large castings Long mold manufacturing cycle

Customizable surface treatment

for aluminum casting products

polishing

Aluminum alloy has a good luster, and the aesthetic appeal of aluminum alloy metal can be presented by polishing to remove the casting texture on the surface of the casting.

Sand blasting and shot blasting:

low-cost surface treatment, uniformly increase the surface texture of aluminum alloy castings, remove surface impurities and oil stains, generally used as a pretreatment step for coating treatment.

Spray painting:

Evenly spray paint or PVDF coating on the surface of aluminum alloy castings, which can effectively enhance the appearance of the surface and increase the anti-oxidation effect. Customizable color and anti-corrosion properties.

Power coating

It can present excellent appearance and increase the abrasion resistance of aluminum alloy castings. It is usually used in daily consumer goods and public facilities. It can customize the color and texture effect.

How to choose casting technology

for your aluminum alloy casting project?

aluminum die casting

aluminum sand casting

aluminum Permanent mold casting

cost

High

low

Economical

efficiency

Highest

high

high

volume-produce

more than 100.000 pieces

10 - 10.000

1.000 - 100.000

mold

die steel

Wood & Aluminum & die steel

die steel

prototype

-

Rapid Prototype

-

Surface roughness

Ra 1.6- Ra3.2

Ra 6.3

Ra3.2 -Ra 6.3

Common defects

Deformation, larger draft angle

sand hole. stomata. Not enough details

stomata

Aluminum alloy casting

has the advantages of application

Aluminum alloy castings have excellent surface finish as well as excellent durability and material stability, which is the main reason why most engineering designers choose aluminum alloy castings, and the benefits of aluminum alloy castings are proved from the actual case of Supro MFG is widely used. With the continuous improvement and progress of non-ferrous metal casting technology, it is helpful for designers’ creative inspiration and technological innovation.

Design flexibility

Aluminum castings can create products with a variety of dimensional accuracy, complex structures, curved shapes, and performance configurations, from die-cast eyewear parts weighing less than 1g, to automotive engine casings, wheels, and important components in the aerospace industry. Products can be manufactured efficiently according to requirements, and after a small amount of precision machining, it is close to the expected perfect precision parts.

Feature

The material properties of aluminum alloy castings can promote product designers to have more functional requirements for products, such as: non-magnetic products, severe corrosion resistance, complex cavity structures, thin-walled products, and heat dissipation and other functions, aluminum alloys Castings are your first choice.

Efficient manufacturing

Faster and higher quality product manufacturing process is what all manufacturers expect. At Supro MFG, through reasonable arrangement of aluminum alloy casting process and quality control process, we can ensure that products are manufactured efficiently, maintain a high level of quality, and fully meet the The required requirements and functions, relying on aluminum alloy cast parts, assemblies and components, are more efficient than any other form of production.

High strength and light weight

This is one of the most significant features of aluminum alloy castings, surpassing any other metal and alloy materials. The excellent strength-to-weight ratio makes aluminum alloys in the same structure, the strength is not inferior to steel materials, and has very little weight, increasing the product. The application life and mechanical bearing capacity are widely used.

Aesthetic visual appearance

Aluminum alloy castings not only have the characteristics of being very strong and lightweight, but also the aesthetic surface treatment and metallic luster are important reasons why aluminum castings are widely cited. These applications can often be seen in daily necessities, and they will not be used for a long time. And wear and tear does not impress people like him, without having to make design tweaks and designs.

low cost

All industries have a soft spot for low-cost product manufacturing. Reducing production costs and obtaining high-quality products is the goal that the manufacturing industry has always pursued. Most of the cost-saving methods are from high efficiency and reduced processing. These characteristics are One of the core technologies of aluminum alloy castings, low material cost, high-efficiency operation, a small amount of precision machining and durable quality can all pass the low-cost advantage to manufacturers and buyers, making it easier to develop products sales market.

special corrosion resistance

At Supro MFG, we maintain a long-term supply relationship with many purchasers in the chemical industry and outdoor products industry. Aluminum alloy castings have very strong corrosion resistance, and are usually used in equipment accessories and outdoor technical facilities of chemical companies. Long-term protection in coastal areas In the harsh environment of the city, it will not be subject to large-scale oxidation and corrosion, which enhances the service life and reliability of the product, and obtains greater market value in long-term applications.

aluminum casting parts

automotive

Motorcycle parts

electronic

Military industry

agricultural machinery

Aerospace

LED accessories